H-304

H-304

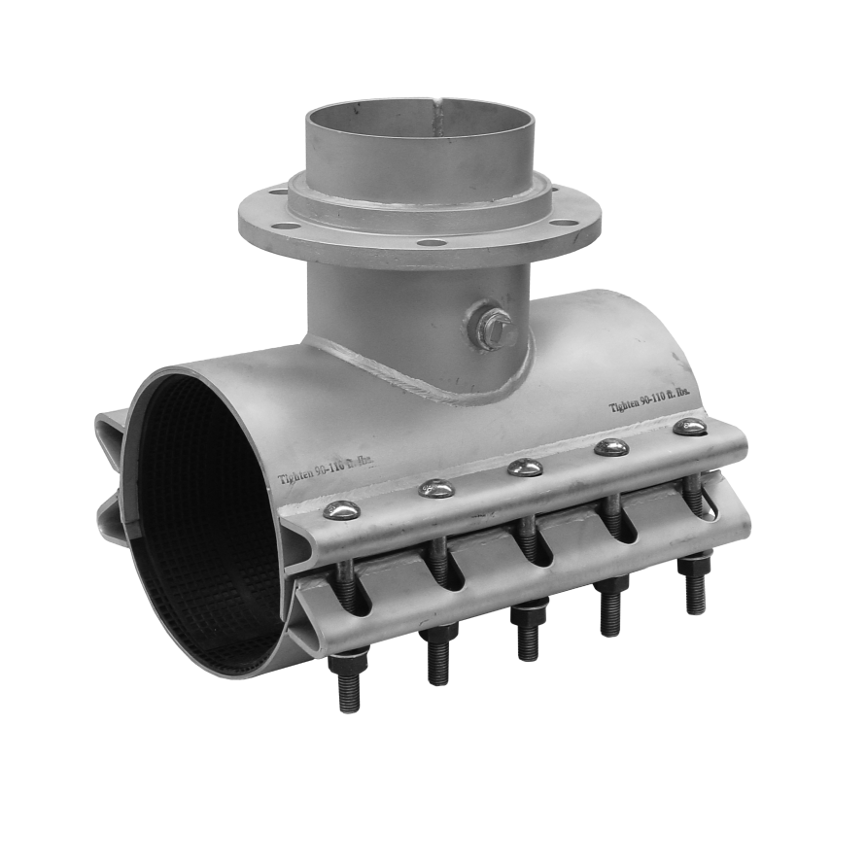

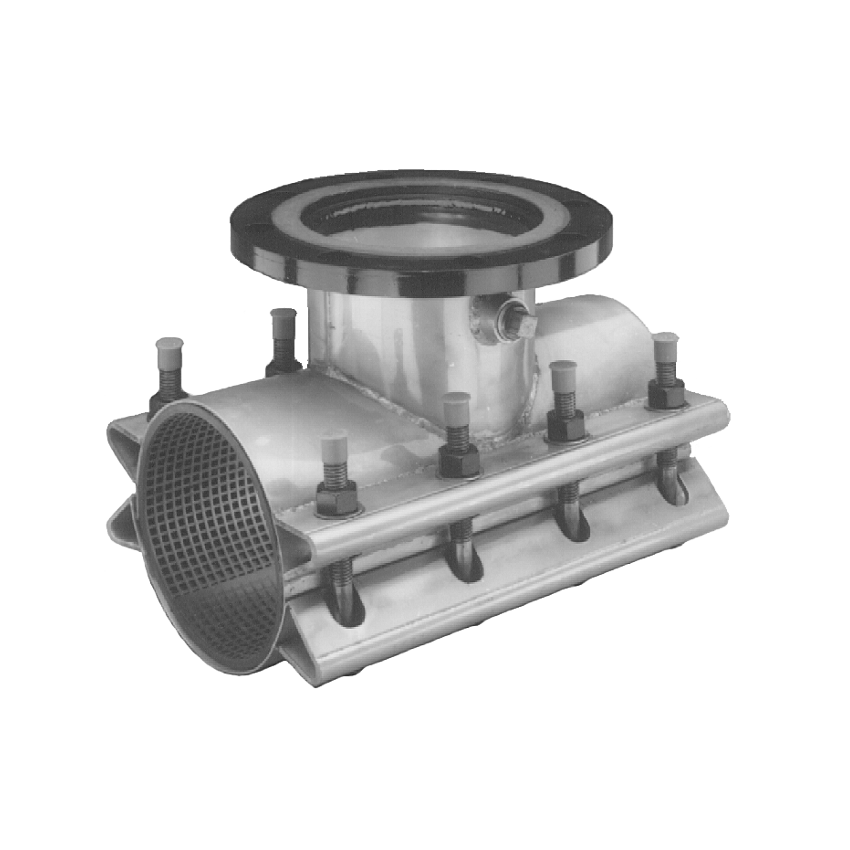

Stainless Steel Tapping Sleeve

Catalog number: H-304

Specifications:

- Sizes-4"-24" main and outlet (see chart below for available size combinations).

- Outlet choices: flange or integral MJ outlet.

- Outlet flange material options: 304L Stainless steel, carbon steel, or ductile iron outlet flange which meets or exceeds all applicable requirements of ANSI B16.1, class 125 and B16.42 class 150 and in accordance with MSS-SP60

- Integral MJ flange is 304L stainless steel.

- Certified to ANSI/NSF 61.

- 3/4" NPT brass test plug (Stainless Steel optional).

- 4"-12" sizes--250 psig (1725 kPa/17 barg) maximum working pressure.

- 14"-24" sizes--200 psig (1375 kPa/14 barg) maximum working pressure.

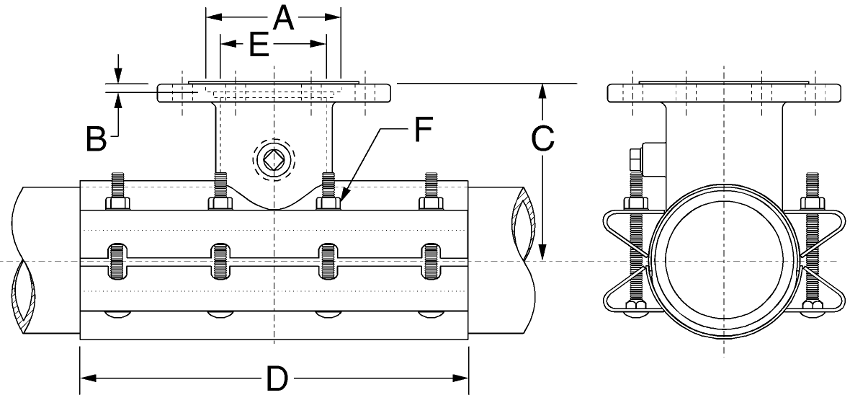

Nominal Size | Dimensions* |

Bolts Per Side | |||||

Outlet Flange† | Sleeve | ||||||

Main | Outlet | A | B | C | D | E | F |

4" | 4" | 5.0315 | .25 | 7.00 | 15 | 4.50 | 4 |

6" | 4" | 5.0315 | .25 | 7.50 | 15 | 4.50 | 4 |

6" | 6" | 7.0315 | .31 | 8.00 | 15 | 6.50 | 4 |

8" | 4" | 5.0315 | .25 | 8.50 | 15 | 4.50 | 4 |

8" | 6" | 7.0315 | .31 | 9.00 | 15 | 6.50 | 4 |

8" | 8" | 9.0315 | .31 | 9.50 | 18 | 8.50 | 6 |

10" | 4" | 5.0315 | .25 | 10.00 | 15 | 4.50 | 4 |

10" | 6" | 7.0315 | .31 | 10.50 | 15 | 6.50 | 4 |

10" | 8" | 9.0315 | .31 | 11.00 | 18 | 8.50 | 6 |

10" | 10" | 11.0315 | .31 | 11.50 | 24 | 10.50 | 8 |

12" | 4" | 5.0315 | .25 | 12.00 | 15 | 4.50 | 4 |

12" | 6" | 7.0315 | .31 | 12.00 | 15 | 6.50 | 4 |

12" | 8" | 9.0315 | .31 | 12.00 | 18 | 8.50 | 6 |

12" | 10" | 11.0315 | .31 | 12.00 | 24 | 10.50 | 8 |

12" | 12" | 13.0315 | .31 | 12.00 | 30 | 12.50 | 8 |

14" | 4" | 5.0315 | .25 | 13.63 | 15 | 4.50 | 4 |

14" | 6" | 7.0315 | .31 | 13.63 | 15 | 6.50 | 4 |

14" | 8" | 9.0315 | .31 | 13.63 | 18 | 8.50 | 6 |

14" | 10" | 11.0315 | .31 | 13.63 | 24 | 10.50 | 8 |

14" | 12" | 13.0315 | .31 | 13.63 | 30 | 12.50 | 8 |

16" | 4" | 5.0315 | .25 | 14.59 | 15 | 4.50 | 4 |

16" | 6" | 7.0315 | .31 | 14.59 | 15 | 6.50 | 4 |

16" | 8" | 9.0315 | .31 | 14.59 | 18 | 8.50 | 6 |

16" | 10" | 11.0315 | .31 | 14.59 | 24 | 10.50 | 8 |

16" | 12" | 13.0315 | .31 | 14.59 | 30 | 12.50 | 8 |

18" | 4" | 5.0315 | .25 | 16.00 | 15 | 4.50 | 4 |

18" | 6" | 7.0315 | .31 | 16.00 | 15 | 6.50 | 4 |

18" | 8" | 9.0315 | .31 | 16.00 | 18 | 8.50 | 6 |

18" | 10" | 11.0315 | .31 | 16.00 | 24 | 10.50 | 8 |

18" | 12" | 13.015 | .31 | 16.00 | 30 | 12.50 | 8 |

20" | 4" | 5.0315 | .25 | 16.88 | 15 | 4.50 | 4 |

20" | 6" | 7.0315 | .31 | 16.88 | 15 | 6.50 | 4 |

20" | 8" | 9.0315 | .31 | 16.88 | 18 | 8.50 | 6 |

20" | 10" | 11.0315 | .31 | 16.88 | 24 | 10.50 | 8 |

20" | 12" | 13.0315 | .31 | 16.88 | 30 | 12.50 | 8 |

24" | 4" | 5.0315 | .25 | 19.00 | 24 | 4.50 | 8 |

24" | 6" | 7.0315 | .31 | 19.00 | 24 | 6.50 | 8 |

24" | 8" | 9.0315 | .31 | 19.00 | 24 | 8.50 | 8 |

24" | 10" | 11.0315 | .31 | 19.00 | 24 | 10.50 | 8 |

24" | 12" | 13.0315 | .31 | 19.00 | 30 | 12.50 | 10 |

†With MJ option, this flange is replaced by an integral SS outlet pipe extension and MJ gland welded permanently in place allowing the sleeve to bolt directly to the outlet of any standard MJ valve. Dimensions for MJ option are compatible with standard connections, and A and B dimensions in chart do not apply.

Tapping Sleeve Pipe Information

Size of main | Size of outlet glange | Available sleeve O.D. ranges | Class and type of pipe | |

4" | 3", 4" | 4.50-4.90 | 114.30-124.46 | Iron pipe size PVC: C900 Cast Iron O.D. PVC; Cast iron 100-250 A, B, C, D; Ductile Iron; AC 100 |

4.80-5.00 | ||||

6" | 4", 6" | 6.59-6.99 | 167.39-177.55 | Iron pipe size PVC: C900 Cast Iron O.D. PVC; Cast iron 100-250 A, B, C, D; Ductile Iron; AC 100, 150 |

6.89-7.30 | 175.00-185.42 | |||

7.10-7.50 | 180.34-190.50 | |||

7.40-7.80 | 187.96-198.12 | |||

8" | 4", 6" | 7.90-8.30 | 200.66-210.82 | Iron pipe size PVC: C900 Cast Iron O.D. PVC; Cast Iron 100-250 A, B, C, D; Ductile Iron; AC 100, 150, 200 |

4", 6", 8" | 8.62-9.06 | 218.95-230.12 | ||

9.04-9.45 | 229.62-240.03 | |||

9.20-9.60 | 233.68-243.84 | |||

9.60-10.00 | 243.84-254.00 | |||

10" | 4", 6", 8" | 9.90-10.30 | 251.46-261.62 | Iron pipe size PVC: C900 Cast Iron O.D. PVC; Cast Iron 100-250 A, B, C, D; Ductile Iron; AC 100, 150, 200 |

4", 6", 8", 10" | 10.73-11.13 | 272.54-282.70 | ||

11.05-11.45 | 280.67-290.83 | |||

11.70-12.10 | 297.18-307.34 | |||

12.00-12.40 | 304.80-314.96 | |||

12" | 4", 6", 8", 10", 12" | 12.50-12.90 | 317.50-327.66 | C900 Cast Iron O.D. PVC; Cast Iron 100-250 A, B, C, D; Ductile Iron; AC 100, 150, 200; C905 IPS O.D. PVC (14") |

13.16-13.56 | 334.26-344.42 | |||

13.60-14.09 | 345.44-378.46 | |||

14.10-14.58 | 358.14-370.33 | |||

14" | 4", 6", 8", 10", 12" | 15.25-15.65 | 387.35-397.51 | C905 Cast Iron O.D. PVC; Cast Iron 100-250 A, B, C, D; Ductile Iron; AC 100, 150, 200; C905 IPS O.D. PVC (16") |

15.60-16.00 | 396.24-406.40 | |||

16.38-16.73 | 416.05-424.94 | |||

16.48-16.88 | 418.59-428.75 | |||

16" | 4", 6", 8", 10", 12" | 17.40-17.80 | 441.96-452.12 | C905 Cast Iron O.D. PVC; Cast Iron 100-250 A, B, C, D; Ductile Iron; AC 100, 150, 200; C905 IPS O.D. PVC (18") |

17.54-17.94 | 334.26-344.42 | |||

17.85-18.25 | 445.52-463.55 | |||

18.15-18.55 | 461.01-471.17 | |||

18.60-19.00 | 472.44-482.60 | |||

18" | 4", 6", 8", 10", 12" | 19.30-19.70 | 490.22-500.38 | C905 Cast Iron O.D. PVC; Cast Iron 100-250 A, B, C, D; Ductile Iron; C905 IPS O.D. PVC (20") |

19.70-20.10 | 500.38-510.54 | |||

20" | 4", 6", 8", 10", 12" | 21.40-21.80 | 543.56-553.72 | C905 Cast Iron O.D. PVC; Cast Iron 100-250 A, B, C, D; Ductile Iron |

21.90-22.30 | 556.26-566.42 | |||

22.30-22.70 | 566.42-576.58 | |||

24" | 4", 6", 8", 10", 12" | 23.30-23.70 | 591.82-601.98 | C905 cast iron O.D. PVC; Cast Iron 100-250 A, B, C, D; Ductile Iron |

23.80-24.10 | 604.52-612.14 | |||

25.60-26.00 | 650.24-660.40 | |||